Introduction

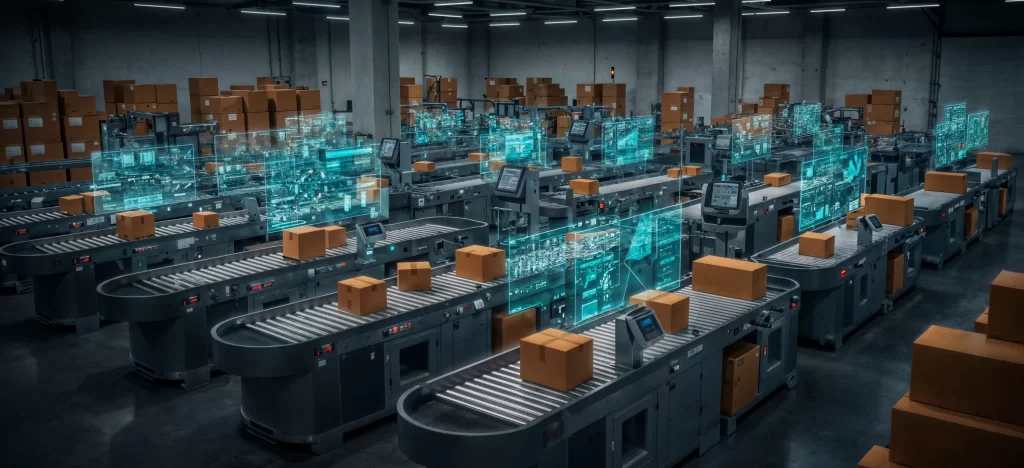

Not all factory problems come with warning signs. A tiny vibration today could lead to a major breakdown tomorrow. Modern factories are evolving into intelligent ecosystems. As industrial operations become smarter, there’s a growing shift from reacting to problems to predicting them.

In this blog, we dive into how predictive analytics is changing the way factories approach equipment health, leading to safer, and more efficient operations.

What makes predictive analytics work

Rather than responding to problems after they occur, predictive maintenance focuses on identifying early warning signs. This is made possible through a combination of real-time data and intelligent analysis.

Sensors and Industrial IoT (IIoT) devices capture everything from temperature and vibration to pressure, voltage, and runtime cycles. These streams of machine data are fed into cloud computing platforms for secure, long-term storage.

Smart dashboards make predictive maintenance actionable. They present equipment insights in an organized view, making it easier for teams to monitor performance and catch irregularities. AI algorithms then analyze this data to detect anomalies.

How smart systems improve performance

Smart factories bring more than just automation. They bring foresight. By using connected systems and real-time insights, manufacturers can plan better and run operations more smoothly.

Predictive maintenance improves overall efficiency. Targeted actions, driven by early alerts, reduce routine maintenance and consumable costs, freeing resources for other priorities.

This approach also enhances product quality, as machines operate under optimal conditions. With fewer unexpected disruptions, manufacturers benefit from more consistent output and longer equipment lifespan.

How Vistrian tools power smart factories

Transforming a factory into a data-driven environment starts with having the right systems in place. Vistrian’s suite of tools supports this transformation by connecting machines, capturing real-time data, and translating it into meaningful action.

FactoryLOOK connects directly with machine controllers and IIoT sensors, enabling continuous data acquisition from key sources. This data is digitized through e-Recording and stored for long-term analysis using a historian system.

Smart dashboards and reports make this data actionable, allowing operators and managers to monitor factory activity in real time and track key performance metrics.

Vistrian’s MMS streamlines maintenance through automated work orders, structured checklists, TPM tracking, and calibration management. FMS extends this control across the facility, managing preventive schedules, spare parts, and high-value components. With features like inventory tracking and stakeholder reporting, it ensures that critical resources are always available when needed.

Conclusion

As factories grow smarter, predictive analytics is becoming essential to modern operations. By leveraging real-time data and connected systems, manufacturers can boost uptime, improve efficiency, and build long-term reliability.