1. What is Vistrian and how does it help manufacturers improve operations?

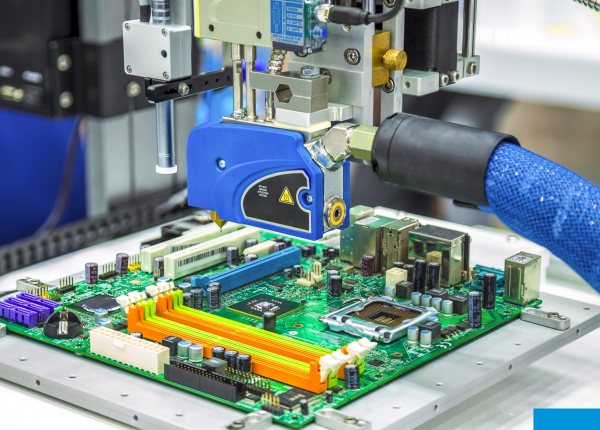

Vistrian delivers advanced Manufacturing Intelligence solutions that empower manufacturers to drive operational excellence across process engineering, equipment, and facility management. Through its suite of software tools, Vistrian enables real-time insights via dashboards, analytics, and alerts-helping businesses enhance OEE, yield, utilization, traceability, and speed to market.

These Industrial IoT solutions are actively deployed in sectors like semiconductors, automotive, biotech, food processing, and more across the US and Asia. Founded in 2002, Vistrian supports global digital transformation from its offices in California, Bangalore, and Kuala Lumpur.

2. What is FactoryLOOK and how does it support real-time factory monitoring?

FactoryLOOK is Vistrian’s real-time factory monitoring software that connects to machines, metrology tools, and IoT devices to collect and analyze production data. It transforms this data into actionable insights, enabling operators and managers to make data-driven decisions on the shop floor.

By offering instant visibility into production processes, FactoryLOOK supports Smart Manufacturing goals like reducing downtime, improving throughput, and enhancing quality control.

3. How does Vistrian Analytics enable predictive maintenance in manufacturing?

Vistrian Analytics works alongside FactoryLOOK to detect early warning signals in production equipment and processes. These insights allow manufacturers to take preventive action before failures occur, significantly improving equipment uptime and reducing maintenance costs.

This combination of real-time data and AI-driven analytics enables predictive maintenance strategies, helping factories shift from reactive to proactive operations.

4. What industries are best suited for Vistrian’s IIoT and smart factory solutions?

Vistrian’s Industrial IoT and Smart Manufacturing solutions are industry-agnostic and scalable. From high-tech manufacturing to automotive, semiconductors, energy storage, and textiles, the platform supports diverse use cases with configurable modules.

Its flexibility and proven deployments make it ideal for any organisation aiming to adopt Industry 4.0 technologies and unlock real-time operational visibility.

5. What is the difference between Vistrian MMS and traditional maintenance systems?

Traditional maintenance systems often rely on spreadsheets and paper-based records, which are hard to manage, audit, and scale. These methods limit traceability, delay insights, and depend heavily on manual inputs.

VistrianMMS digitalizes the entire maintenance lifecycle-work orders, checklists, spare parts, and calibration tracking-all in one platform. It integrates with FactoryLOOK to enable condition-based and predictive maintenance, supporting both TPM and audit-readiness with real-time dashboards and automated records.

6. How does Vistrian MES improve production efficiency and traceability?

VistrianMES tracks manufacturing batches through every production stage, collecting detailed process data and surfacing critical metrics for daily operations. It ensures consistent quality and operational control while reducing cycle times.

With integrated traceability features, VistrianMES can provide unit-level visibility, supporting regulatory compliance, recalls, and continuous improvement initiatives in manufacturing environments.

7. Can Vistrian software be integrated with existing factory systems?

Yes. Vistrian products are designed for easy integration with legacy systems, ERP platforms, and third-party software. Data flows can be bi-directional, allowing seamless interoperability with existing infrastructure.

Whether implemented as a complete suite or modularly, Vistrian’s platform adapts to the factory’s current tech stack-ensuring minimal disruption during digital transformation.

8. How does Vistrian use AI and machine learning in its platform?

Vistrian leverages AI and machine learning to identify patterns, predict failures, and optimize production workflows. These capabilities enhance decision-making by providing real-time recommendations based on historical and live factory data.

9. What kind of dashboards does Vistrian offer for plant visibility?

Vistrian offers customizable dashboards tailored to operators, supervisors, and managers. These dashboards present real-time KPIs, alerts, and trends-supporting better visibility across production, maintenance, and quality operations.

10. How quickly can a manufacturing unit implement Vistrian solutions?

Depending on the customer’s readiness and scope, Vistrian’s software can be deployed in as little as 3 to 4 weeks. The company offers full implementation support-including system integration, configuration, and user onboarding.

This rapid deployment helps factories begin their digital transformation journey without extended downtime or disruption.