Introduction

Pharma manufacturing operates in one of the most highly regulated environments in the world. With every batch tied to patient safety, manufacturers must maintain flawless documentation, real-time visibility, and strict compliance with FDA, EMA, and global GMP standards. Yet traditional paper-based batch records continue to slow down production, introduce manual errors, and complicate audits.

This is where digital batch records transform the way life sciences plants operate.

Digital Transformation for Modern Batch Execution

As the life sciences industry shifts toward smaller, flexible, and more personalized production, traditional documentation systems can’t keep pace. Unified, data-driven batch record management has become essential for maintaining agility without compromising accuracy.

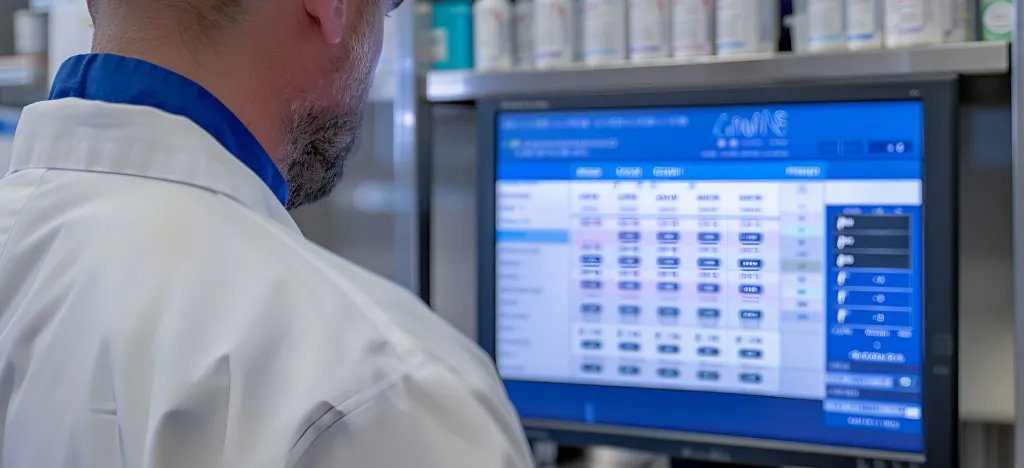

Vistrian brings together recipe control, batch tracking, and process visibility into one digital ecosystem. By automating documentation and capturing process data in real time, manufacturers ensure every step is recorded, verified, and traceable.

This prevents deviations from slipping through, strengthens compliance, and accelerates batch release.

End-to-End Traceability Through Integrated Systems

Digital batch records powered by Vistrian replace manual paperwork with electronic documentation, audit trails, and automated checks. From material addition, operator input, equipment status to process condition is captured and time stamped.

This unified approach delivers:

- Full traceability across batches, materials, equipment, and operators

- Electronic signatures and GMP-compliant audit trails for regulatory approvals

- Error-proof recipe execution through automated instructions and limit checks

- Real-time deviation detection to reduce rework and prevent non-compliance

With visibility across every unit operation, teams spend less time on paperwork and more time optimizing production.

Quality, Compliance, and Speed: All in One Platform

Vistrian’s integrated IIoT and process automation backbone ensures pharma manufacturers maintain consistent quality across runs. Continuous process monitoring reduces variability, while digital records simplify regulatory submissions and accelerate product launches.

In an industry where precision is non-negotiable, digital batch records powered by Vistrian redefine traceability and compliance; creating a foundation for agile, reliable, and future-ready pharma manufacturing.