Introduction

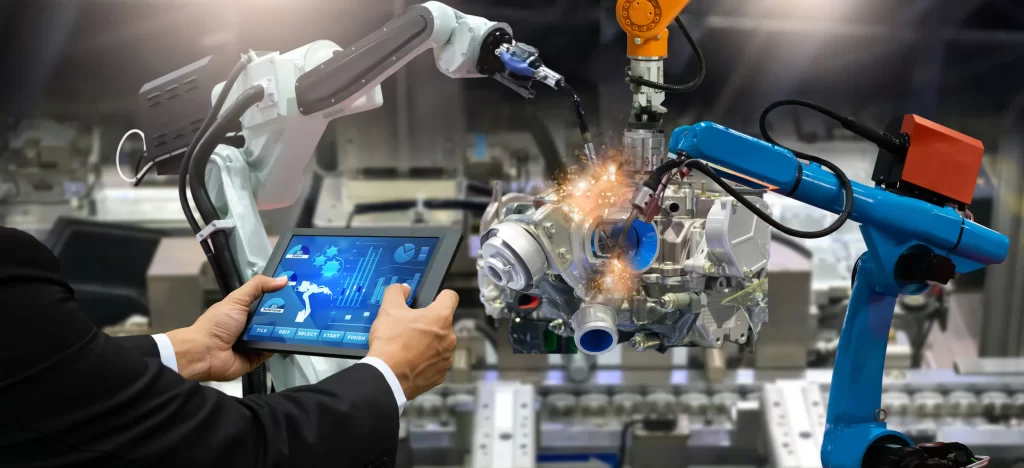

High-tech manufacturing operates in a world where speed, precision, and customisation define success. From advanced electronics to life sciences and microdevices, every component passes through tightly controlled production processes that demand flawless synchronization.

Yet, even with cutting-edge automation, inefficiencies can creep in with an unnoticed equipment lag, a delayed material transfer, or a temperature fluctuation that throws production off balance.

This is where Industrial IoT (IIoT) transforms the game by connecting sensors, systems, and machines into a single intelligent network. By enabling real-time visibility and automation, IIoT ensures every process is not only monitored but also optimized for peak performance.

Real-Time Data from the Factory Floor

IIoT sensors are the backbone of connected high-tech manufacturing. They continuously capture precise data from every corner of the production line; from machine temperature and vibration to environmental parameters like humidity, airflow, and power usage.

The result is a self-aware production environment that continuously senses, learns, and adapts. This level of operational transparency minimizes bottlenecks, stabilizes throughput, and safeguards quality consistency across high-volume, high-precision lines.

Predictive Intelligence through IIoT Dashboards

Real-time data is powerful, but predictive insight is transformational. IIoT dashboards and analytics tools create a digital twin of the production line. By analyzing live and historical sensor data, these systems can simulate outcomes, forecast failures, and identify process inefficiencies before they impact production.

For example, predictive algorithms can detect gradual temperature drifts in coating systems or airflow imbalances in cleanrooms that could compromise product quality. Maintenance teams receive early alerts, enabling timely interventions instead of emergency repairs. Meanwhile, production managers can visualize performance trends across multiple facilities and fine-tune operations remotely.

This proactive approach eliminates unplanned downtime, extends equipment lifespan, and enhances yield by turning data into a continuous improvement engine.

Implementing IIoT in High-tech Manufacturing

For high-tech manufacturers ready to embrace IIoT, the journey begins with connecting existing assets and data silos into a unified system. Vistrian’s suite of smart manufacturing solutions, particularly FactoryLOOK makes this transition seamless.

FactoryLOOK integrates effortlessly with MES, ERP, and SCADA systems to capture data from hundreds of tools in real time. It enables engineers to monitor key performance metrics, visualize process health, and respond instantly to anomalies. By transforming raw data into actionable intelligence, FactoryLOOK bridges the gap between process visibility and decision-making.

Vistrian’s solutions empower manufacturers to achieve:

- Improved equipment performance through data-driven diagnostics.

- Reduced lead times by eliminating manual inefficiencies.

- Lower maintenance costs with predictive upkeep.

- Greater operational flexibility through scalable, intelligent automation.

In an era where the high-tech industry is racing toward personalization, sustainability, and zero-defect manufacturing, Industrial IOT enables digital transformation without disrupting existing infrastructure.