Introduction

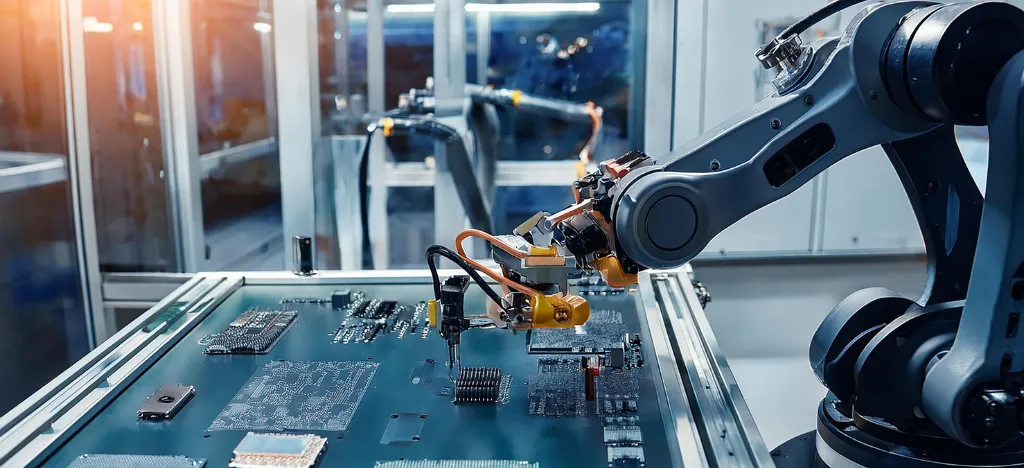

Downtime is one of the costliest challenges in manufacturing. Predictive maintenance is changing that. By using real-time data, analytics, and intelligent alerts, manufacturers can anticipate failures before they happen, reducing unplanned downtime, extending equipment life, and improving operational efficiency.

What is Predictive Maintenance?

Predictive maintenance (PdM) is a strategy that monitors the condition and performance of equipment during normal operations. Using data from sensors, machine logs, and other inputs, it predicts when a component is likely to fail, allowing teams to intervene before it does. This approach minimizes disruptions and ensures repairs are scheduled at the most optimal time.

How Predictive Maintenance Works

1. Data Collection

Sensors installed on machinery collect continuous data such as temperature, vibration, pressure, and speed. This data is streamed into a centralized platform for analysis.

2. Data Analysis

Advanced analytics and machine learning models assess patterns, detect anomalies, and estimate the remaining useful life of components. The system learns what ‘normal’ looks like for each machine and flags any deviation.

3. Actionable Alerts

When an issue is detected, predictive maintenance systems send alerts to maintenance teams with suggested actions. This ensures maintenance happens just in time – not too early, and never too late.

Benefits of Predictive Maintenance

– Reduces unplanned downtime and costly repairs.

– Extends equipment lifespan through timely intervention.

– Minimizes labor costs and inventory waste.

– Enhances safety by preventing sudden equipment failures.

– Increases overall productivity and asset reliability.

FactoryLOOK and Predictive Maintenance

Vistrian’s FactoryLOOK platform enables real-time visibility into machine performance. By aggregating data from across the factory floor, it supports predictive maintenance strategies through contextual insights, live alerts, and historical trend analysis. FactoryLOOK helps manufacturers not only monitor their assets but also predict and prevent failures before they disrupt production.

Conclusion

Predictive maintenance is no longer a future ideal – it’s a present-day necessity. With the right data and tools like FactoryLOOK, manufacturers can stay ahead of breakdowns, reduce costs, and keep their operations running smoothly and safely.