Introduction

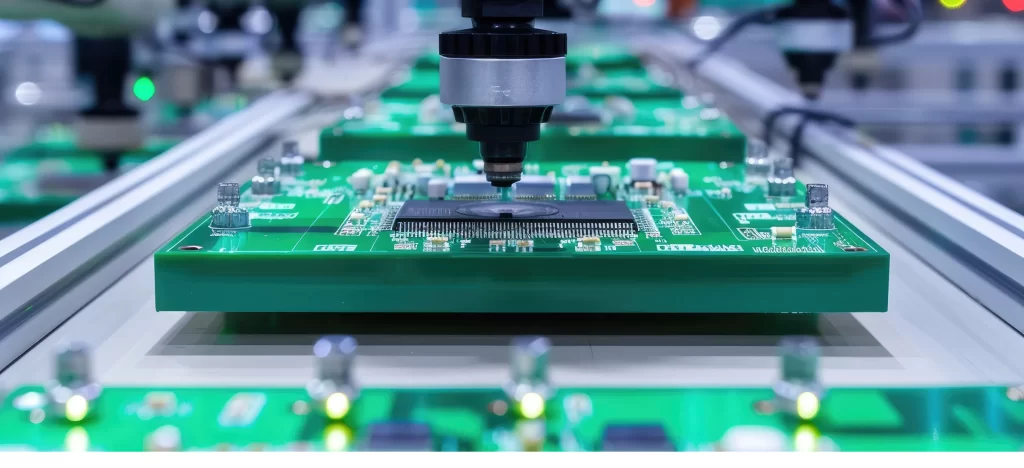

Semiconductor manufacturing is one of the most complex and precise production processes in the world. With thousands of steps from wafer fabrication to testing, each process must occur under ultra-clean, tightly controlled conditions. Even the slightest variation in temperature, vibration, or pressure can lead to microscopic defects that compromise entire batches, resulting in costly rework or scrapped wafers.

Tracking these details manually or through isolated systems often leads to blind spots, making it difficult to identify bottlenecks or root causes quickly.

This is where Industrial IoT (IIoT) becomes a game-changer by connecting every sensor, tool, and process into a unified, intelligent ecosystem that offers real-time visibility and control.

Real-Time Monitoring: Seeing Beyond the Surface

IIoT sensors form the foundation of real-time semiconductor monitoring. These smart devices continuously measure critical parameters like temperature, humidity, vibration, air pressure, and chemical concentration with millisecond precision.

In a fab where each wafer can go through hundreds of steps, these sensors ensure that no process variable goes unnoticed.

For example, vibration sensors detect abnormalities in etching or polishing tools before they impact wafer uniformity, while pressure and flow sensors track the performance of vacuum systems and gas lines critical for cleanroom stability.

This constant data stream allows fabs to maintain process consistency and environmental integrity. What is the outcome of it? This level of monitoring minimizes yield losses, enhances uptime, and ensures every batch meets the highest quality standards.

Predictive Maintenance: Anticipating Failures Before They Happen

While real-time monitoring tells you what’s happening now, predictive maintenance tells you what’s going to happen next. Using advanced IIoT dashboards and analytics, semiconductor fabs can forecast equipment health and schedule maintenance before failures occur.

Instead of reactive shutdowns that halt production and increase costs, fabs can achieve planned interventions by reducing downtime, extending equipment life, and maintaining throughput stability.

Implementing IIoT in Semiconductor Fabs

For fabs looking to adopt IIoT, the first step is connecting legacy tools, sensors, and control systems under a single data framework. Modern IIoT platforms like Vistrian FactoryLOOK make this possible without overhauling existing infrastructure. FactoryLOOK seamlessly interfaces with MES, ERP, and equipment control systems through standard protocols and APIs, ensuring smooth data flow across the fab floor.

Once implemented, FactoryLOOK collects parameters from hundreds of tools, and can be paired with Vistrian Analytics, Dashboards, VistrianMMS (Maintenance Management Software), and more, to provide manufacturers the right tools to visualize and analyze operations in real-time.

The results are measurable: faster root-cause identification, improved yield consistency, and better equipment utilization. In one implementation, a global semiconductor manufacturer using Vistrian solutions reduced unplanned downtime, detected hidden power surges, and achieved ROI in under six months through data-driven insights.

With solutions like Vistrian FactoryLOOK, Vistrian Analytics, and VistrianMMS, fabs can move from reactive problem-solving to proactive performance management. Because in the world of semiconductors, where every micron matters, clarity and control are the ultimate competitive advantage.