Stay one step ahead with Industry 4.0

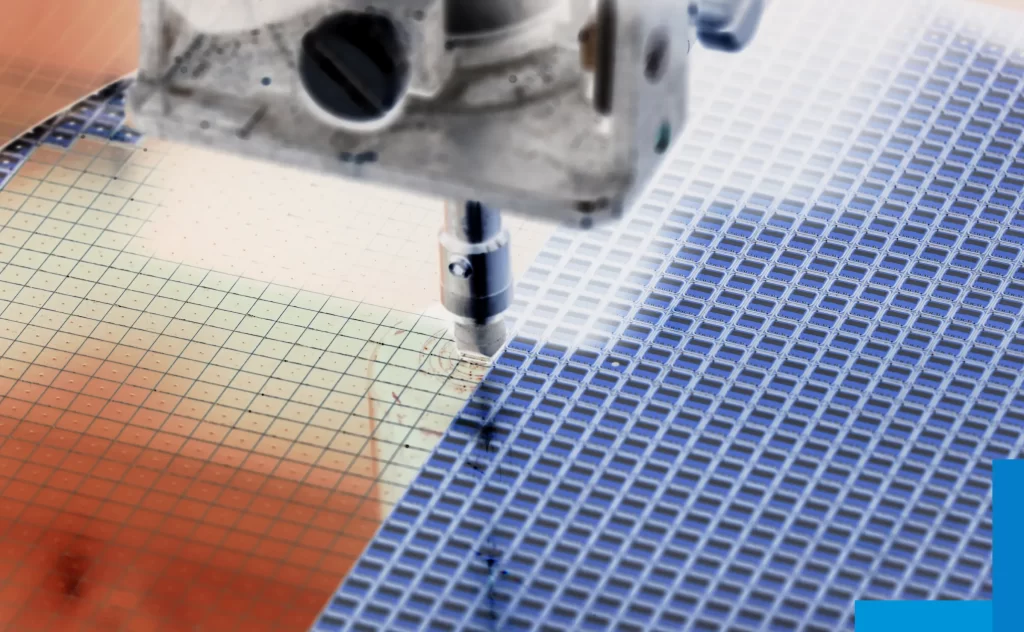

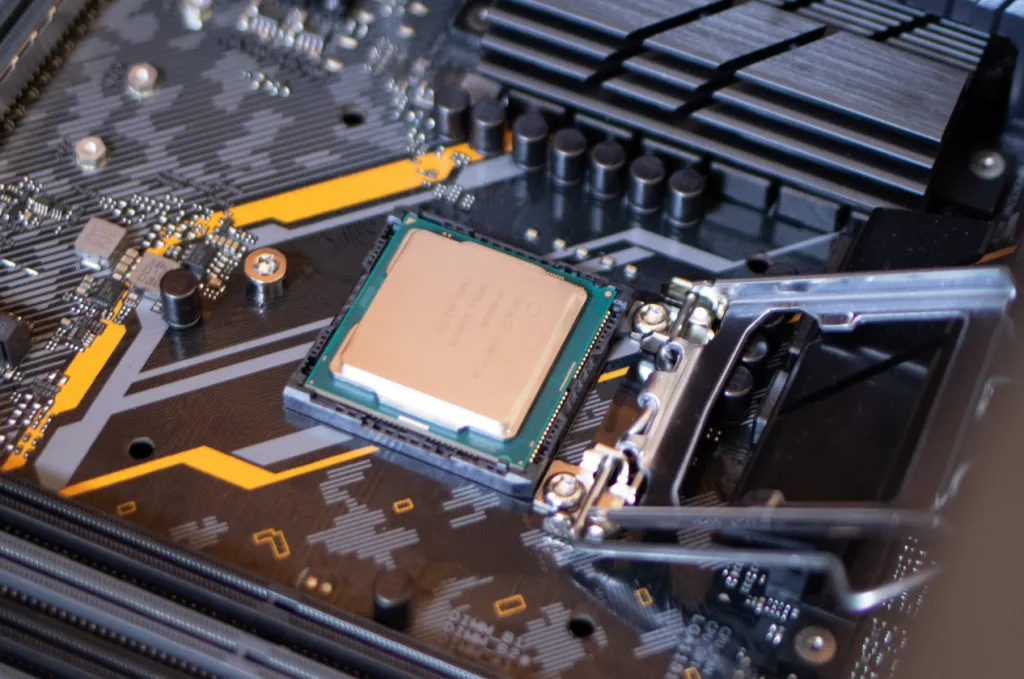

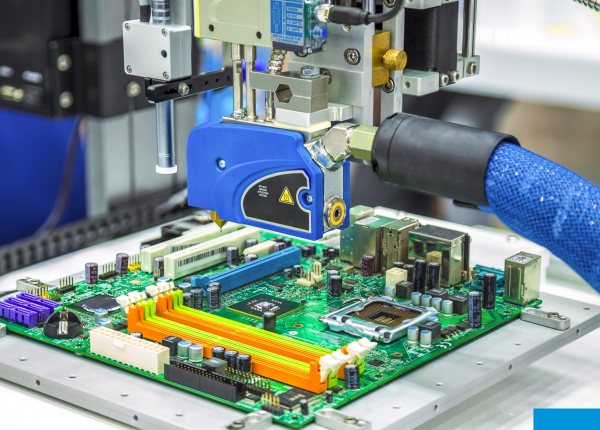

In today’s constantly changing market, semiconductor manufacturers are forced to innovate and meet demands for higher efficiency and reduced costs. In order to remain competitive in the market, semiconductor plants face the need to be flexible at high volume and low costs. To do so, manufacturers require leading-edge Industry 4.0 technology for automation and IOT solutions across the plant.

Digitally transform your semiconductor operations

Enable flexible strategies which accommodates the changing needs of market and customers to meet current and future demands. Vistrian helps the semiconductor industry meet process requirements and keep up to rising customer expectations. By building an architecture which integrates the entire industrial network, Vistrian drives information-driven intelligence and knowledge-driven operations at every level. Enable faster launches with more competitive operations and better efficiency in your semiconductor production.

Benefits

Case Studies

1. How does Vistrian’s FactoryLOOK enhance real-time monitoring in semiconductor manufacturing?

FactoryLOOK provides real-time monitoring by connecting to semiconductor tools, collecting equipment and process data, and delivering immediate visibility through dashboards and alerts. It enables early detection of anomalies and supports predictive maintenance to avoid costly downtimes.

2. What benefits does VistrianMES provide for managing materials and workflows in semiconductor fabs?

VistrianMES tracks materials, jobs, and workflows across cleanroom environments with precision. It ensures complete traceability, streamlines production routing, and enables faster response to process deviations.

3. Can Vistrian’s solutions integrate with existing semiconductor manufacturing systems and equipment?

Yes, Vistrian solutions integrate seamlessly with semiconductor fabs’ existing MES, ERP, and equipment control systems using standard protocols and APIs. This ensures minimal disruption and quick implementation.

4. How does Vistrian’s software contribute to reducing downtime and improving yield in semiconductor production?

Vistrian helps reduce downtime by predicting equipment issues and improving scheduling efficiency. Its real-time data visibility also enables process optimization, which directly impacts yield improvement.

5. What analytics and reporting capabilities does Vistrian offer for semiconductor manufacturing processes?

Vistrian offers analytics such as yield, downtime, WIP tracking, SPC, cycle time, and lot genealogy. Reports can be customized to support audits, quality control, and continuous process improvement.